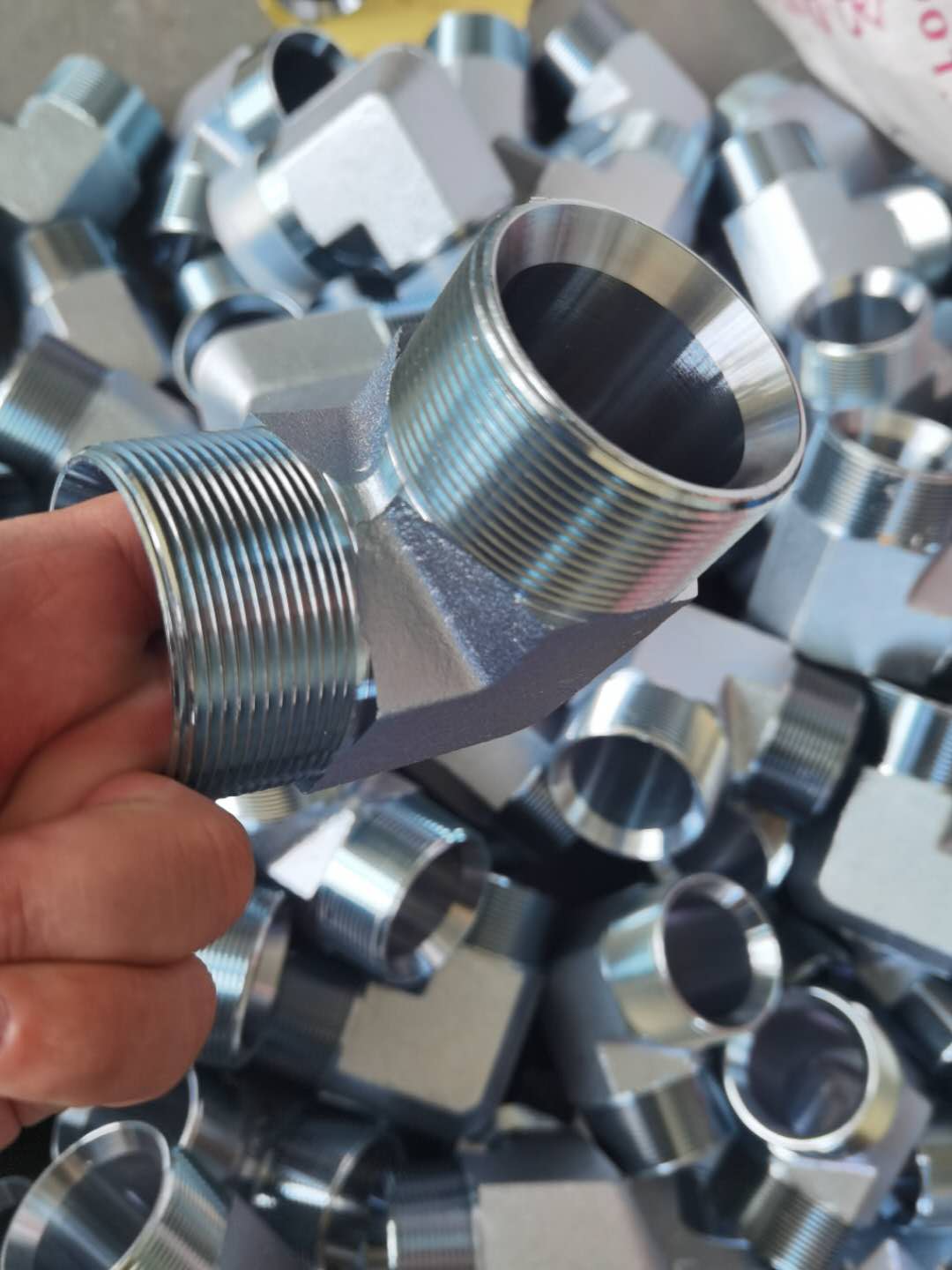

Taper Thread Fitting

Taper Thread Fittings Instructions

NPT、BSTP threads should be assembled with sealant.NPTF is metal to metal seal, but use sealant also. Sealants are available in various of forms such as teflon tape,paste and anaerobic glue etc..

Teflon tape, paste etc.,if applied improperly,they will pollute the oil of the hydraulic system, even jam the system.

The seal of the small thread is better than the large.In general the seal of less than 3/4”are good.

The connect will compact when the taper thread for straight fitting,if for eblow or tee or cross fittings,the assemble angle is difficult to contron, so suggest that the adjustable stud end fittings should be used,for example ISO6149,ISO11926 etc..

Taper Thread Fittings Assembly Instructions

Assembly

Inspect port and connector to ensure that threads an both are free of drit,burrs and excessive nicks.

Apply sealant to male pipe threads.With any sealant, the first and the second threads should be uncovered to avoid system contamination.If Teflon tape is used it should be wrapped 1.1/2 to 2 turns in clockwise direction when viewed from the pipe thread end.

First tighten the fitting with hand,then tighten with a wrench 1.1/2 to 3 turns..In general,the small fitting is tighten about 2.5 turns and the large fitting is tighten about 2 turns.

Reassembly

The taper thread fitting can be reassembled.When reassembled,check if sealant has worn thin.

Leakage reason

1,There is no sealant used or sealant has worn thin.

2,Threads are galled.

3,Fitting screwing in too far into the port.

4,Threads are severely nicked.

5,Threads are loosen.

The latest situation of the epidemic in Yiwu City

Aug. 22, 2022

The latest situation of the epidemic in Yiwu City

Aug. 22, 2022

New coronavirus pneumonia outbreak in Yiwu City

Aug. 19, 2022

New coronavirus pneumonia outbreak in Yiwu City

Aug. 19, 2022

Copyright © Zhejiang Shihui Hydraulic Machinery Co.,Ltd. All Rights Reserved | Sitemap |